Garnet ProPeL app for iPhone and iPad

Developer: Garnet Instruments Ltd.

First release : 14 Feb 2017

App size: 18.35 Mb

Pressure overage Protect and event Logger (ProPeL)

Background:

On the treater truck are two pumps, one low pressure centrifugal (200PSI max) and one high pressure (3000 PSI) triplex. The low pressure pump is more convenient to use but if you expose the outlet to more than 200PSI of pressure you blow out the seals, which are costly to replace and add to the truck’s downtime. There are two possible errors that can lead to this: either attempting to pump into a closed valve on the truck or at the wellhead, or excessive wellhead pressure. This system would monitor the pressure at the pump outlet and shut down the pump if the pressure is excessive. It will also provide a warning light if the wellhead pressure is too high, this alerts the operator that the high pressure pump will need to be used. It will also log any shutdown event.

Operational description:

The pressure status at the wellhead connection is shown with an indicator light to alert the operator if the wellhead pressure is high or low. If the pressure is high it tells the operator that the high pressure pump must be used. The pressure at the pump outlet is monitored as well; if this pressure exceeds 200PSI then the hydraulic bypass relay is turned off, activating the hydraulic bypass and shutting down the pump. This way if the high pressure warning is ignored or the operator forgets to open the discharge valve from the pump, the pump is shut down to save the pump seals. The pump status is indicated on the front panel with either a green “PUMP ACTIVE” LED or a red “VALVE/PRESSURE ERROR” LED.

Once the pump is shut down, it can only be restarted by pressing the Acknowledge button, the pump will not restart by itself when the pressure drops. The ACK button will not work if the pump discharge pressure is still too high. Any shutdown event and acknowledgement event is logged. The log has the time and date, the event (shutdown or acknowledge), and the pressure status for both pressure sensors.

The front panel has the ACK button, the pump status indicators, the wellhead pressure status indicators, and the time and date display. The system will also have a couple of spare inputs and outputs to accept additional pressure sensors and to drive a horn or other indicators.

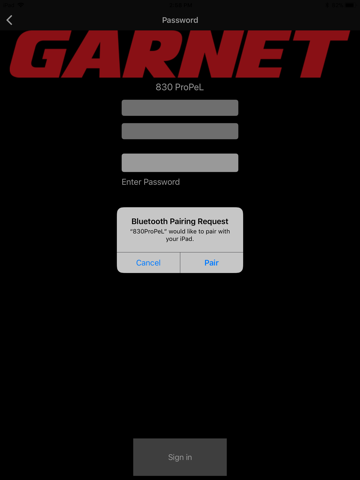

The event log can be downloaded by the truck owner or manufacturer to determine if the pump was abused or not and can be used as evidence in pump warranty claims. The download will be done via a Bluetooth link to a smart phone application. The log can be viewed and emailed using the application in addition to configuring the device name and setting the date and time.